Metal Surface Preparation

Welcome to,

Blast Top, Protecting Your Assets.

“Blast Top helps build brand value with use of Advanced Abrasive Blasting Techniques For Surface Preparation.“

Metal Surface Preparation By Abrasive Blasting-

Blast top is Specialist in Metal Surface preparation By abrasive blast cleaning and the application of protective coatings. Our primary focus is on the application of protective coating systems that provide excellent corrosion control at the best value. In India And World, Abrasive Blasting is A Excellent, Latest, Efficient and Very Popular Method For New Metal, used Metal, Painted Metal & Concrete Surface Cleaning and creating Suitable surface For Coating.

Office Phone

+91 9054353580

Abrasive blasting also known as Sand blasting, Shot Blasting, Grit Blasting.

Sandblasting(Abrasive Blasting) is the process of smoothing and cleaning a hard surface by forcing solid particles across that surface at high speeds using compressed air.

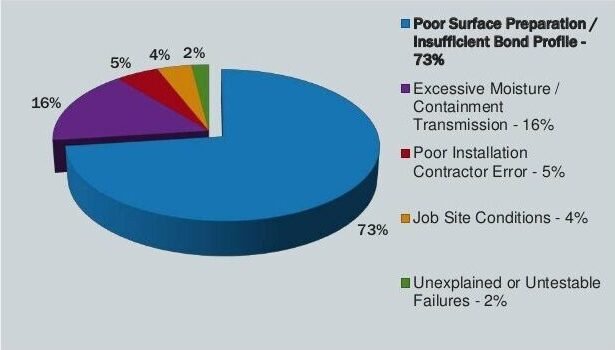

WHY COATING FAIL

Corrosion is a big menace to the economy of the country. The loss due to corrosion has been estimated to be of the order of 2 – 5% of the GDP of any country. In India the losses have been estimated at approximately 25,000 crores rupees per year due to the impact of corrosion according to Newsletter NACE, India [2].

Why is Abrasive Blasting Important for Metal Surface Preparation? (Benefits)

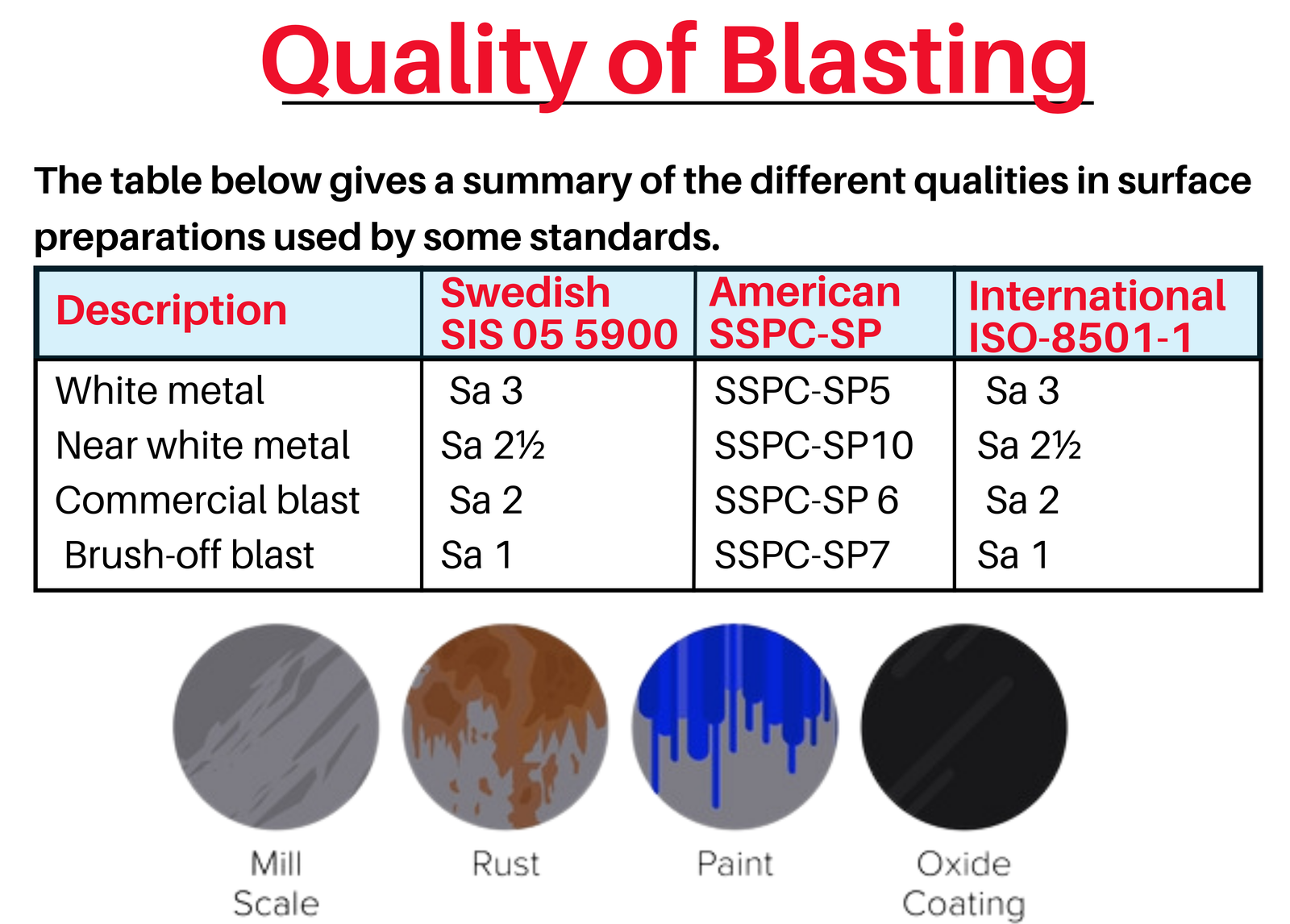

Enhanced Surface Cleanliness: – Abrasive Blasting Process is Best & Efficient Process To be a Surface Free from Mill Scale, Rust, Dust, Old Paint, Old Powder Coating & Other impurities & Contaminants.

Uniform Surface Profile: Abrasive blasting Process is generating a consistent surface profile, which is vital for achieving a uniform appearance and performance of the Protective coating & Final Painting.

This uniformity ensures that coatings are evenly applied and bonded.

Improved Adhesion: By roughening the metal surface, abrasive blasting creates a profile that enhances the adhesion of subsequent coatings. This is critical for the longevity and durability of the coating, ensuring that it does not peel or flake off prematurely.

Corrosion Protection: Proper surface preparation through abrasive blasting removes any corrosive substances and contaminants that could cause future corrosion. This process is essential in prolonging the life of the metal and reducing maintenance costs

That’s why the Abrasive blasting Process helps to build a Brand value By Enhancing Coatings Quality and aesthetic appeal.

What We Offer

Expert in Various Blasting Techniques

Our expertise lies in various blasting techniques that remove impurities, rust, old coatings, and other contaminants from metal surfaces. We utilize advanced technologies and high-quality abrasive materials to achieve optimal surface profiles, ensuring that the final finish adheres perfectly and lasts longer. Our comprehensive range of metal surface preparation services includes Garnet Blasting, C.I. Grit Blasting, Copper Slag Blasting, and Sand Blasting.

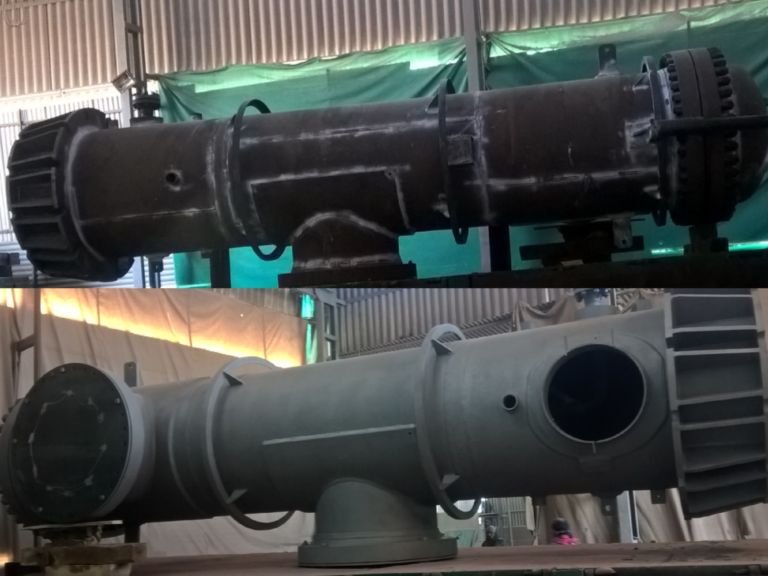

FEATURED PROJECT

Expert Metal Surface Preparation with Advanced Blasting Techniques

We provide expert metal surface preparation using advanced blasting techniques for optimal results.

Aluminium oxide Blasting

Aluminium oxide Blasting is use for Ferrous and Non-Ferrous metal substrates.

Why Choose Our Services for

Metal Surface Preparation?

We pride ourselves on delivering exceptional quality and service in metal surface preparation. Our state-of-the-art equipment, skilled technicians, and commitment to customer satisfaction set us apart in the industry. Whether you’re dealing with complex industrial structures or delicate metal components, we have the expertise to ensure your surfaces are perfectly prepared for whatever finishing process you require.